Ezi Sign and Printers

16-12-2019

CNC Routing

CNC stands for Computer Numerical Control and a CNC Router is a cutting machine designed to cut different sort of hard materials including aluminum, steel, wood, plastic and composites. Such a machine uses computer numerical control technique to transform the path on a design file to an actual cut of the material. Indeed, such a machine is like a CNC mill, but computer-controlled technique is used instead of hand to cut the material.

CNC Routers are manufactured in various shapes and sizes. Some old-fashion industrial CNC Routing machines are quite large and take a lot of space. However, some other models are usually built in sizes that can fit in smaller places and still function the same. There are also desktop versions of CNC Routers that can be used at home and controlled only by a desktop PC at home. However, the medium-sized industrial versions have the best performance for industrial purposes.

Although there are different shapes and sizes of industrial or desktop CNC Routers, but also there are similarity among these different configurations including the existence of a CNC controller, spindle motors, amplifiers, AC inverters, linear guides, screws and workspace bed. These components are basic elements of a functional CNC Router regardless of its shape, where it is used, whether it is built for heavy-duty industrial purposes or home usage or its size.

In short, CNC Routers are powerful industrial cutting machines. When they are combined with laser cutters, it is possible to make precise and nice cuts on woods, plastics, acrylics, and aluminum, composite panels, PVC and foams. In addition, CNC Router brings quite number of benefits for the business including reduction of waste and increase in productivity.

Normally, a computer software is controlling the application of a CNC Router to give it precision cut. Owners of CNC Routers usually have two different set of software system. One is their normal graphic design software that the relevant artwork is created in. The other piece of software is translator of design to a series of G-code instructions that are readable by the CNC cutting machine.

In most cases, after completing the initial design in the graphic design application, the artwork file is sent to the computer controlling the CNC router. Next, the material that is intended to be cut is put on the workspace table of router. The material can be wood, acrylic, PVC, aluminum or any other material suitable for cutting purposes. Then, the operator starts the CNC machine and computer controlling it. Finally, the design is sent to the machine and cutting process is started. Most CNC Router automatically find edges of the material and complete the cut process with high precision.

The language that CNC Routing machine understands is called g-cade. There are specific software products shipped by CNC routers that are able to transfer the CAD drawings or graphic designs into g-code and make them read for process by a CNC router. Indeed, the cut process by the CNC router is all done by a computer rather than a human being. That is why the precision of cuts is quite high, and produced materials are suitable for industrial purposes.

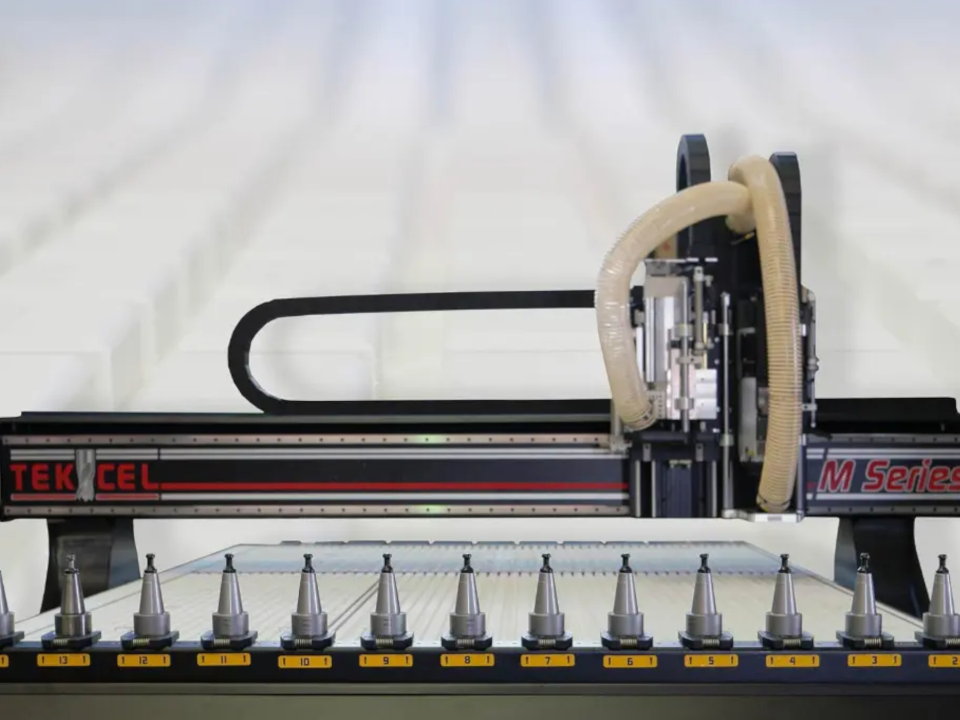

At Ezi Sign and Printers, we use a Tekcel GFX CNC Router at 1,500cm by 2,500cm by 150cm that can cut a large variety of materials at standard industrial sizes. Its 5.5kw HSD spindle motors and robust framework has made it suitable for heavy industrial workloads at high precision and great performance. It has a digital screw system with high accuracy due to automatic sensing of length.

We have produced variety of signs by the help of our CNC Router. The large bed size and high cut quality of Tekcel GFX machine allows us produce beautiful finished materials.

At Ezi Sign and Printers, we can cut the following materials using our CNC Router:

For a productive signage business, the CNC Router can come quite handy to help with cutting materials and making them suitable for the job. We have already had dozen of completed jobs that had some of their parts cut by the CNC Router such as signs, billboards, etc.